Key features

Unique safety protection, anti-scald design, the temperature of the upper and lower ironing heads can be adjusted by the button on the thermostat panel.

The head is made of copper material, which has good heat transfer effect to save power consumption, improve work efficiency, and save energy compared with similar products.

The pressure of the upper and lower heads can be adjusted through the pressure regulator to meet the requirements of different process parameters.

The upper and lower heads are driven by cylinders and guided by two linear guide bushes, which are flexible in the upper and lower movements, and the guidance is accurate to ensure the parallelism of the product after edge banding.

It can be applied to different specifications of product batteries, and the adjustment is simple and convenient, no need to adjust and replace the head.

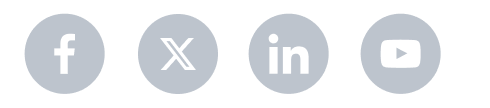

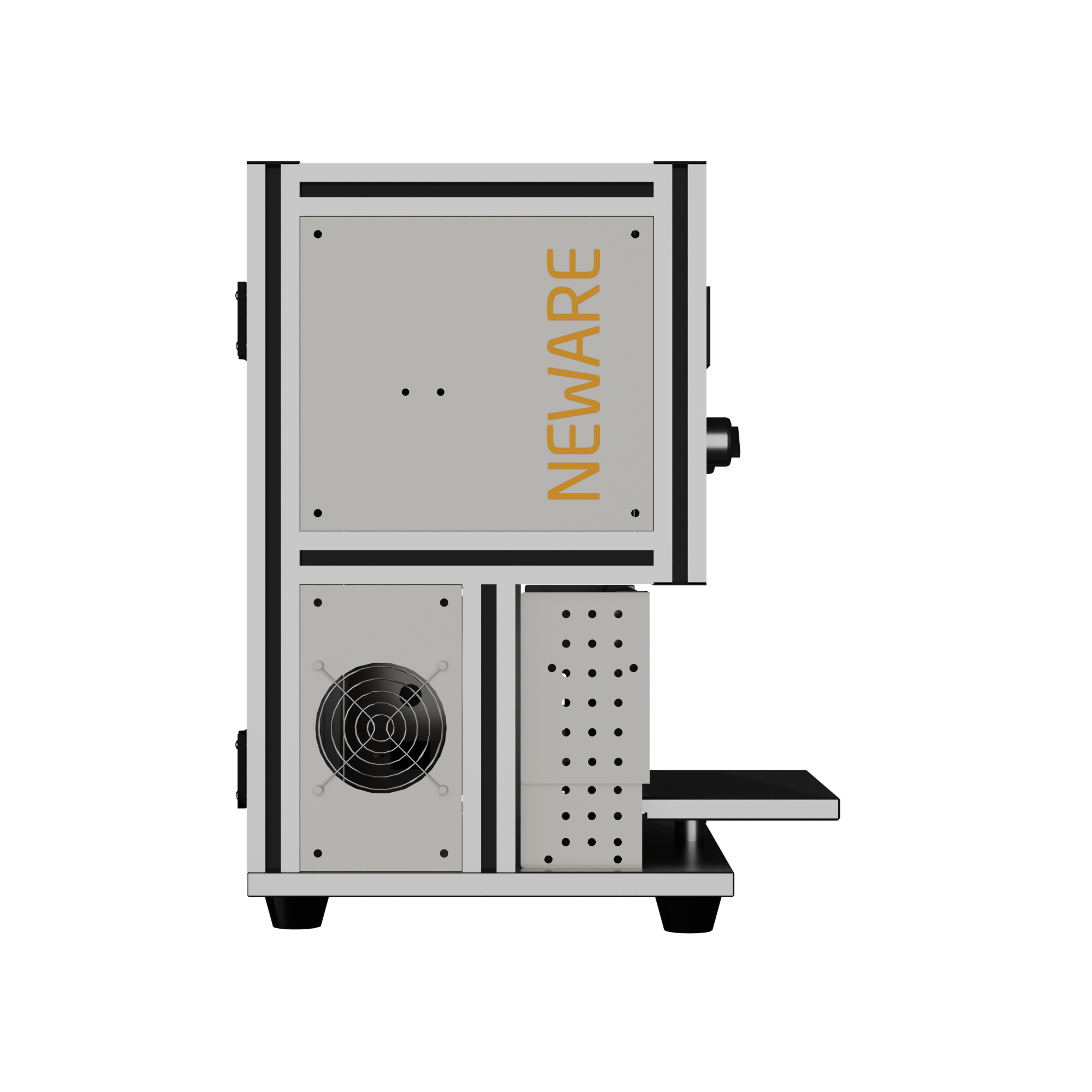

The frame is made of aluminum profile, which has a beautiful appearance; The sheet metal adopts three-dimensional geometric design, which is simple and beautiful.

Small dimensions, smooth and uniform sealing marks, beautiful edge sealing.

Technical parameters

Applicable specifications: side seal ≤ 190mm, top seal 190mm (including air bag).

Sealing knife length: 200mm.

Airbag edge width: 15~90mm.

Seal width: standard 5mm±0.4 (3~10mm optional) replaceable seal knife seal other widths.

Thickness of side banding: 60~300μm (depending on the thickness of aluminum-plastic film).

Thickness of top lug edge sealing: 200~700μm (depending on the thickness of the aluminum-plastic film).

Sealing temperature: room temperature ~ 250°C (temperature can be set freely).

Temperature control accuracy: ± 2°C.

Main body to heat sealing edge: 1~5±0.4mm adjustable.

Packaging time: standard 2s-3s (0-99s adjustable).

Seal thickness accuracy (mm): the difference between the packaging thickness of any two points <15μm.

Equipped with protective device to prevent high temperature scalding.

The equipment has a discharging table.

The device has the function of automatic and manual operation.

The equipment is easy to clean and replace the copper mold.

Compressed air: 5~7kg/cm2.

Air compressor working speed: ≥400 times/hour.

Power supply: AC220V/50Hz.

Power: 1kW.

7.20 Dimensions: L430×W330×H480mm.

7.21 Equipment weight: 35kg.

Categories

Categories