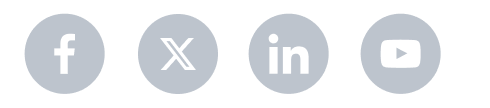

Key features

The head is made of copper material, which has good heat transfer effect to save power consumption, improve work efficiency, and save energy compared with similar products.

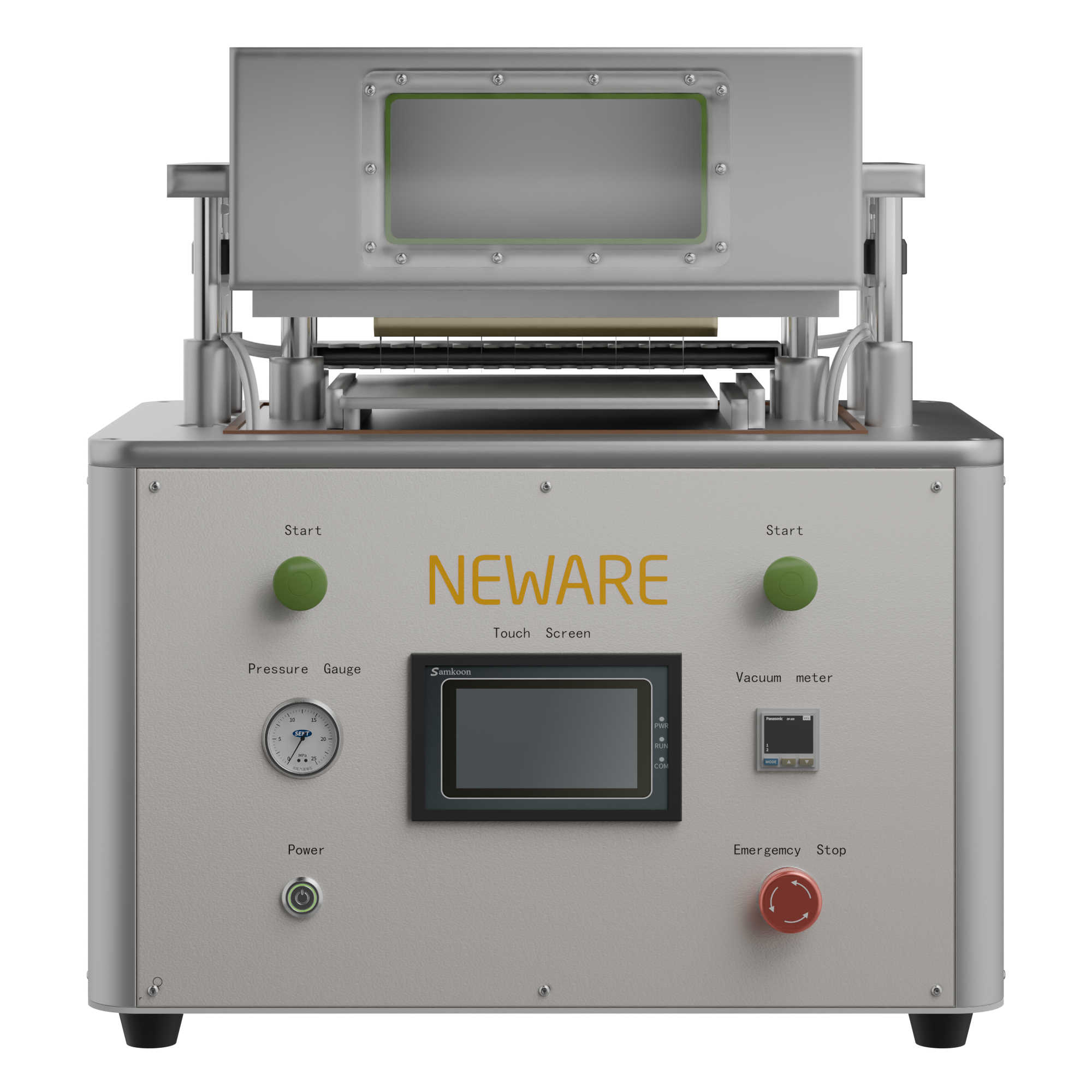

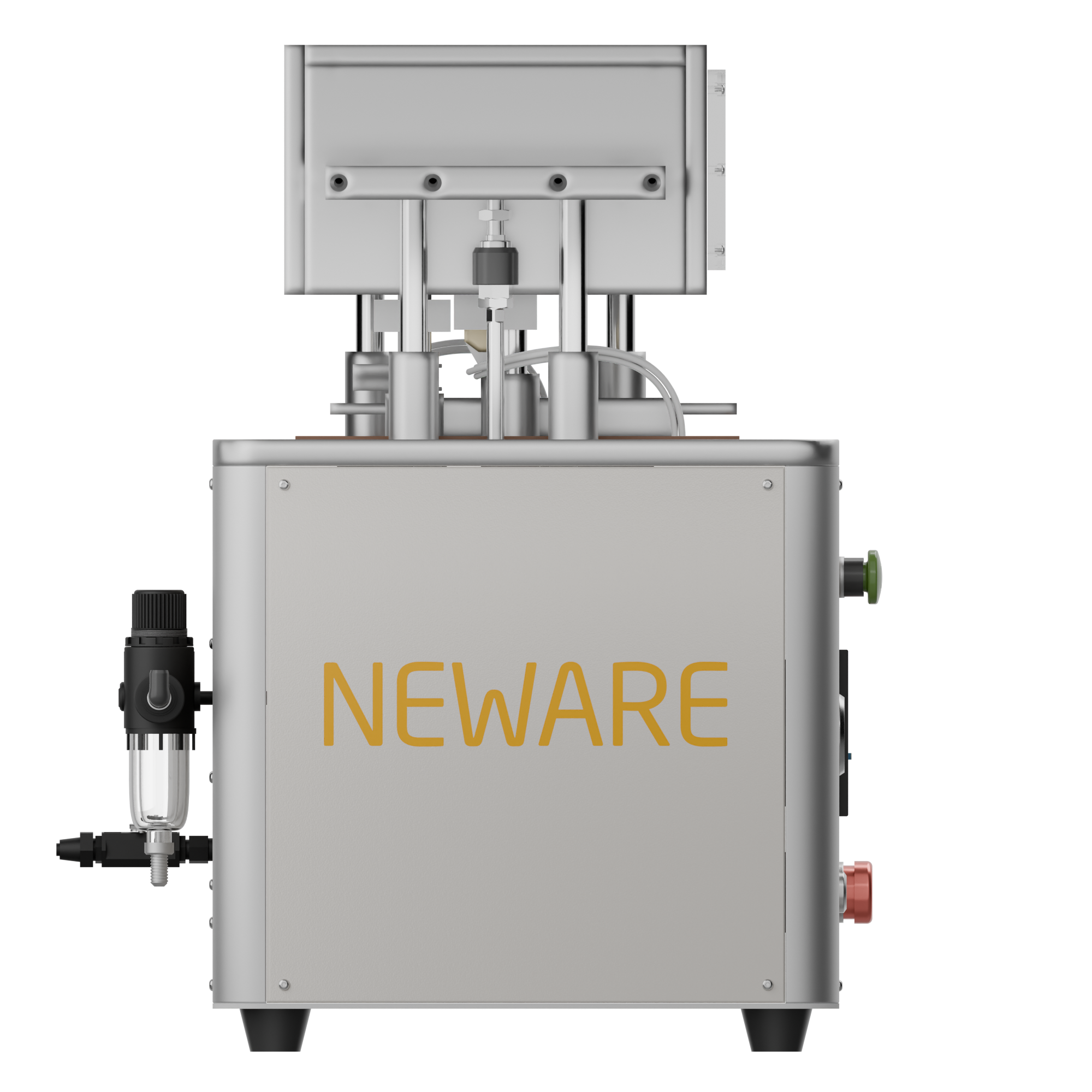

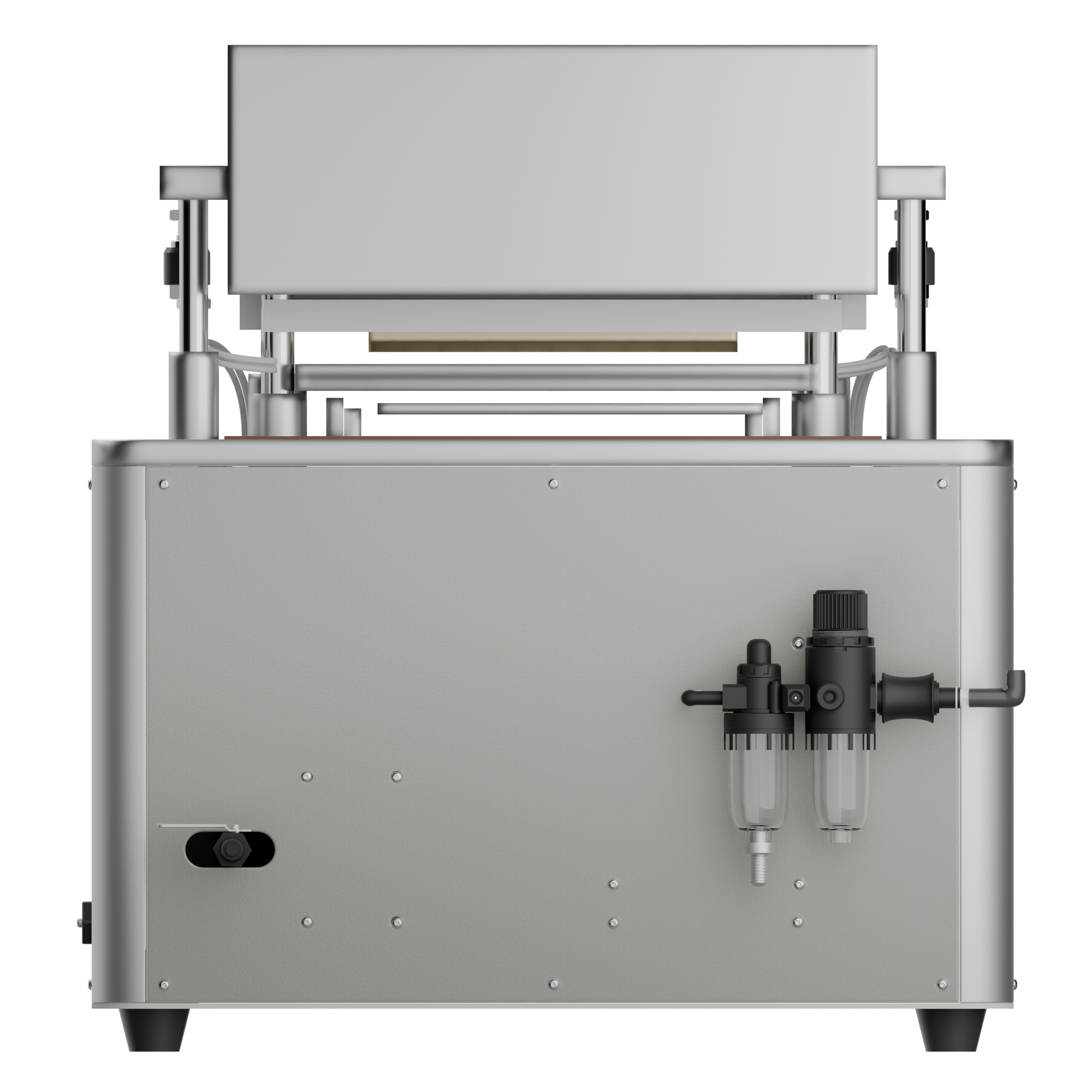

The pressure of the upper and lower heads can be adjusted through the pressure regulator to meet the requirements of different process parameters.

The upper and lower heads are driven by cylinders and guided by two linear guide bushes, which are flexible in the upper and lower movements, and the guidance is accurate to ensure the parallelism of the product after edge banding.

The machine comes with an automatic puncture function.

The cover cavity is driven by a cylinder, guided by a linear guide sleeve, which moves flexibly up and down, and the guidance is accurate to ensure the tightness of the product.

It can be applied to different specifications of product batteries, and the adjustment is simple and convenient.

It is easy to operate, beautiful in appearance, small in size and light in weight.

Technical parameters

Material: the cavity is made of aluminum alloy, which is corrosion-resistant and has a firm structure;

Vacuum degree: vacuum degree≤-96Kpa (the buyer has their own vacuum pump);

Head temperature: room temperature ~ 250°C, temperature is adjustable;

Temperature control accuracy: ±1.5°C;

Heat sealing pressure: 0~7kg/cm2 adjustable;

Heat sealing time: 0~99 seconds adjustable;

Edge banding width: 5±0.4mm (according to customer's requirements);

Maximum edge banding size: 200mm;

Seal thickness range: 60~300μm;

Seal thickness accuracy (mm): the difference between the package thickness at any two points < 15μm;

Air consumption: about 0.2L compressed gas/once per seal;

Air compressor working speed: ≥180 times/h;

Power: 300W heating element, power consumption of about 0.6kW when heating;

Power supply: 220V/50Hz;

Compressed air source: 0.5~0.7Mpa;

Dimensions: 500×550×700mm (L×W×H);

Maximum discharge battery size: as shown below.

Categories

Categories