Key features

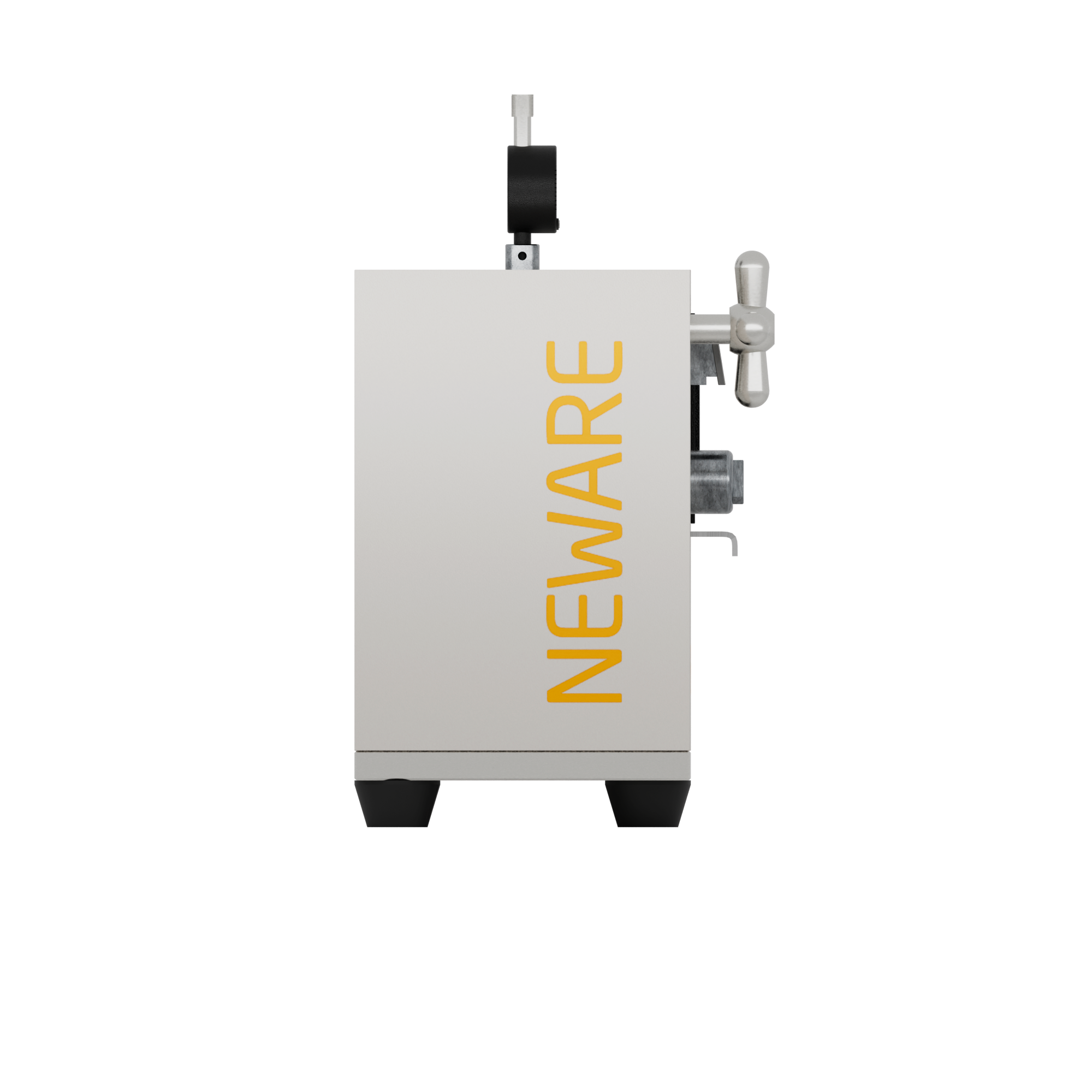

The roll has high hardness, and the surface is hard chrome plating, the hardness can reach HRC62 and has good anti-rust performance.

The oblique block is used to adjust the gap between pressing plates, which has good self-locking and high adjustment accuracy.

Rolling is high-precision, and the cylindricity of the rollers is ≤ ± 2 μ M.

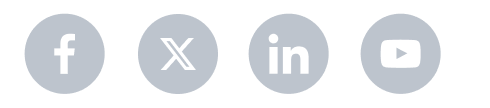

The design is vertical, facilitating the feeding and rolling of sheet and strip materials.

Gear meshing rotation is used to realize the roller pressing.

The thickness and speed of the tablet pressing can be adjusted, and the appearance is exquisite and beautiful.

Rolling is electric, forming is automated, and operation can be forward and reverse.

The volume is small, the operation is simple, and the use is flexible and fast.

Technical parameters

Roll diameter: Φ96mm;

Roller cylindricity ≤±2μm;

Roll hardness: HRC62;

Roller finish: 0.4 or more;

Rolling thickness: 0~2mm gap adjustable;

Rolling pressure: 2~3T;

Tablet width: 0~150mm;

Roll placement: vertical placement;

Tablet thickness, speed can be adjusted;

Mode of operation: electric;

Voltage and frequency: AC220V/50Hz;

Power: 120W;

Feeding speed: 0~40mm/s;

Dimensions: 570×230×330mm (L×W×H);

Weight: 60kg.

Categories

Categories