Key features

The head is made of copper material, good heat transfer effect to save power consumption, improve work efficiency, energy saving than similar products;

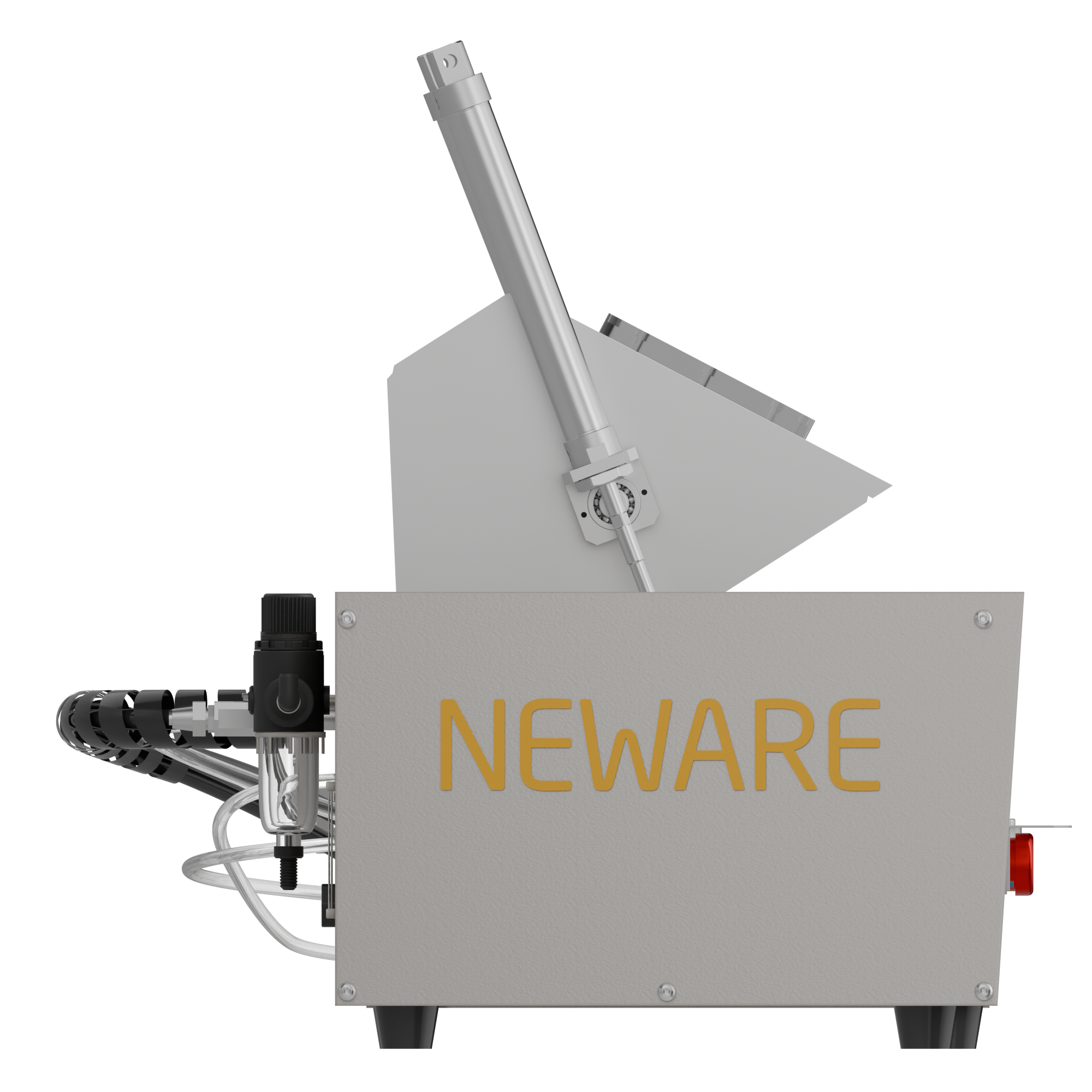

The pressure of the upper and lower head can be adjusted by the regulating valve to achieve different process parameters;

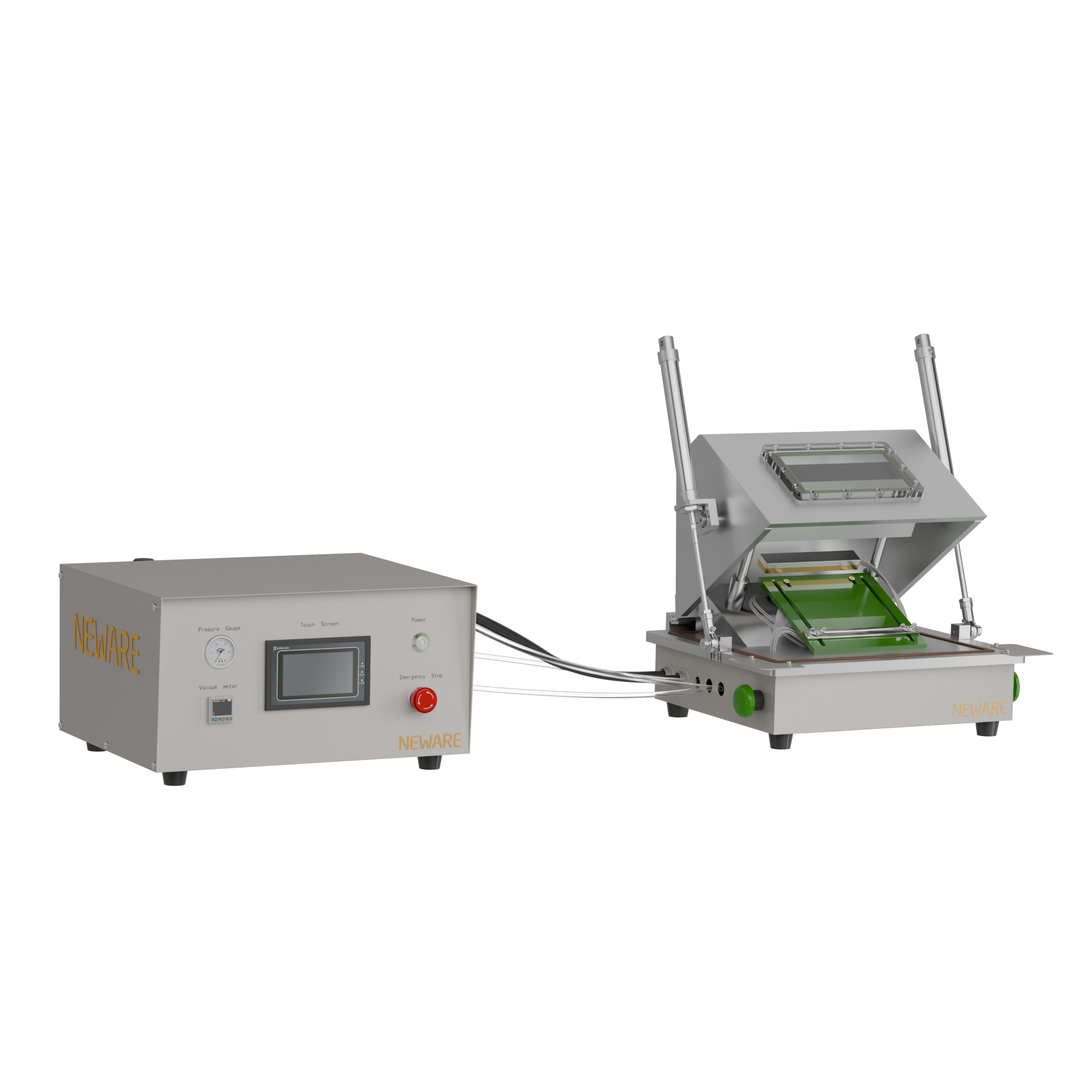

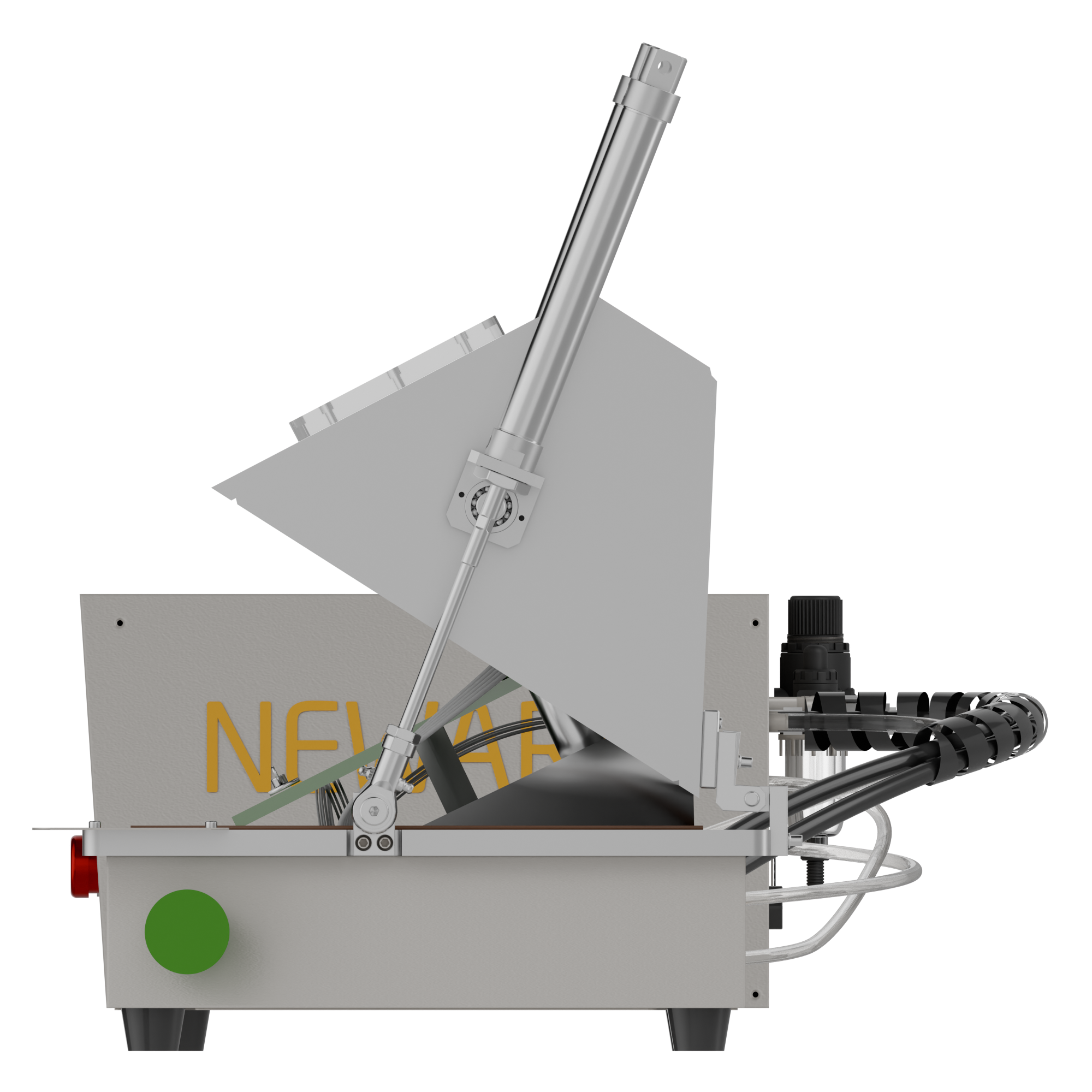

The upper and lower head is driven by cylinder through two linear guide sets, flexible upper and lower activities, accurate guidance to ensure the parallel degree of product edge sealing;

The changes in the cavity can be observed at work through the fluoroscopy window;

The cover cavity is driven by cylinder, through the rotating guide guide, flexible up and down activities, accurate guidance to ensure the product sealing requirements;

Can be applicable to different specifications of the product battery, and simple and convenient adjustment;

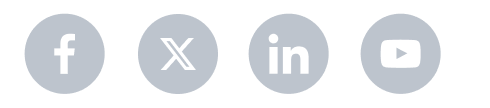

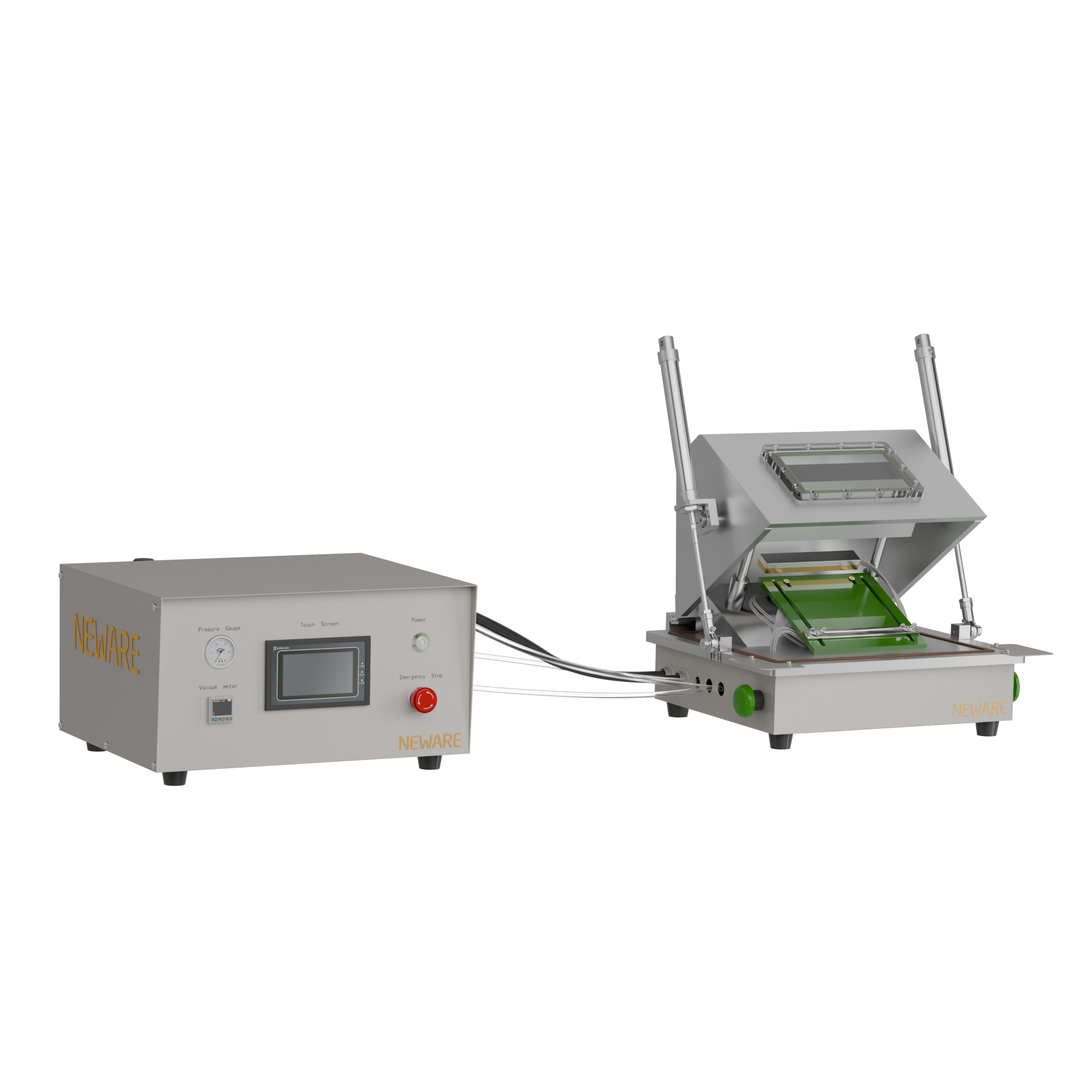

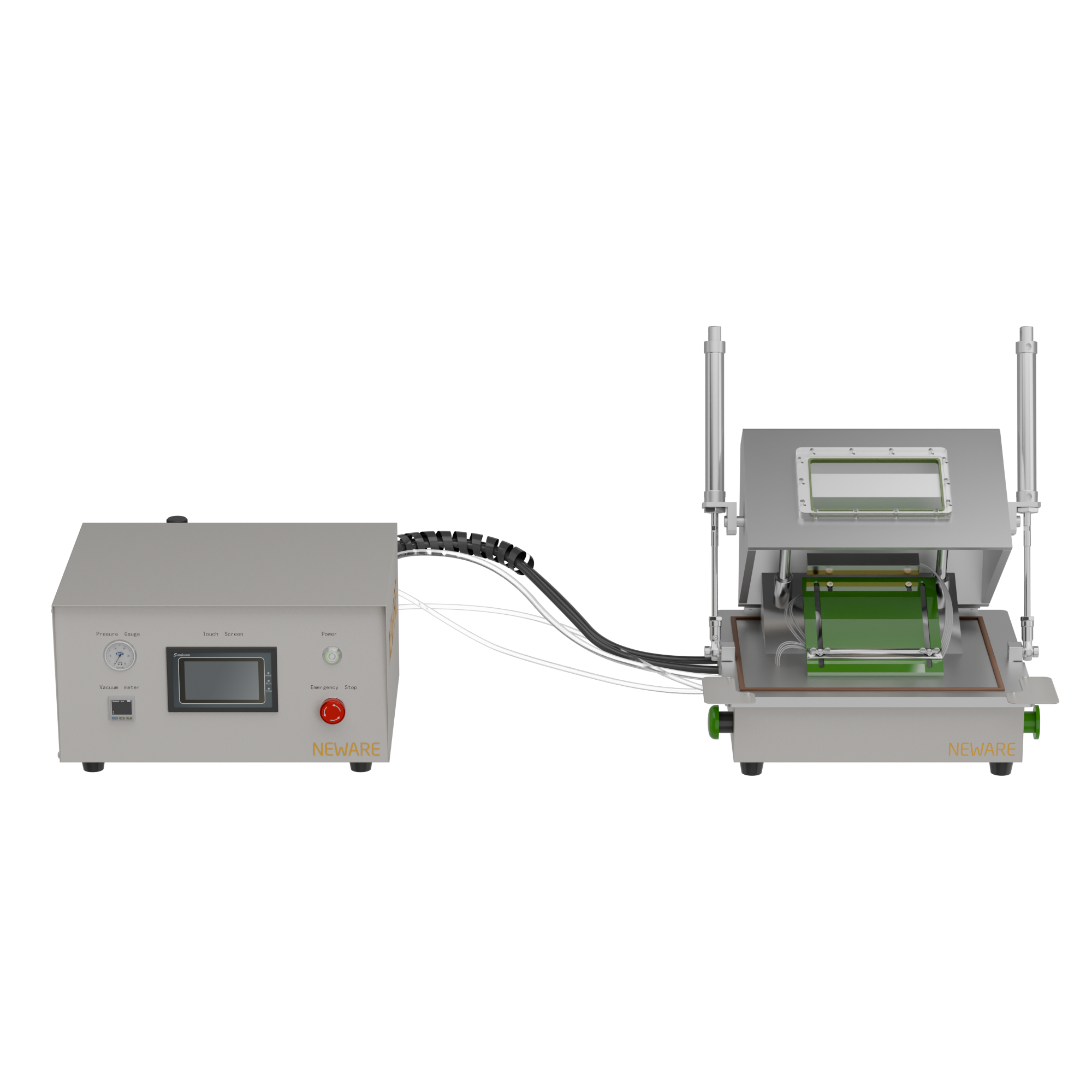

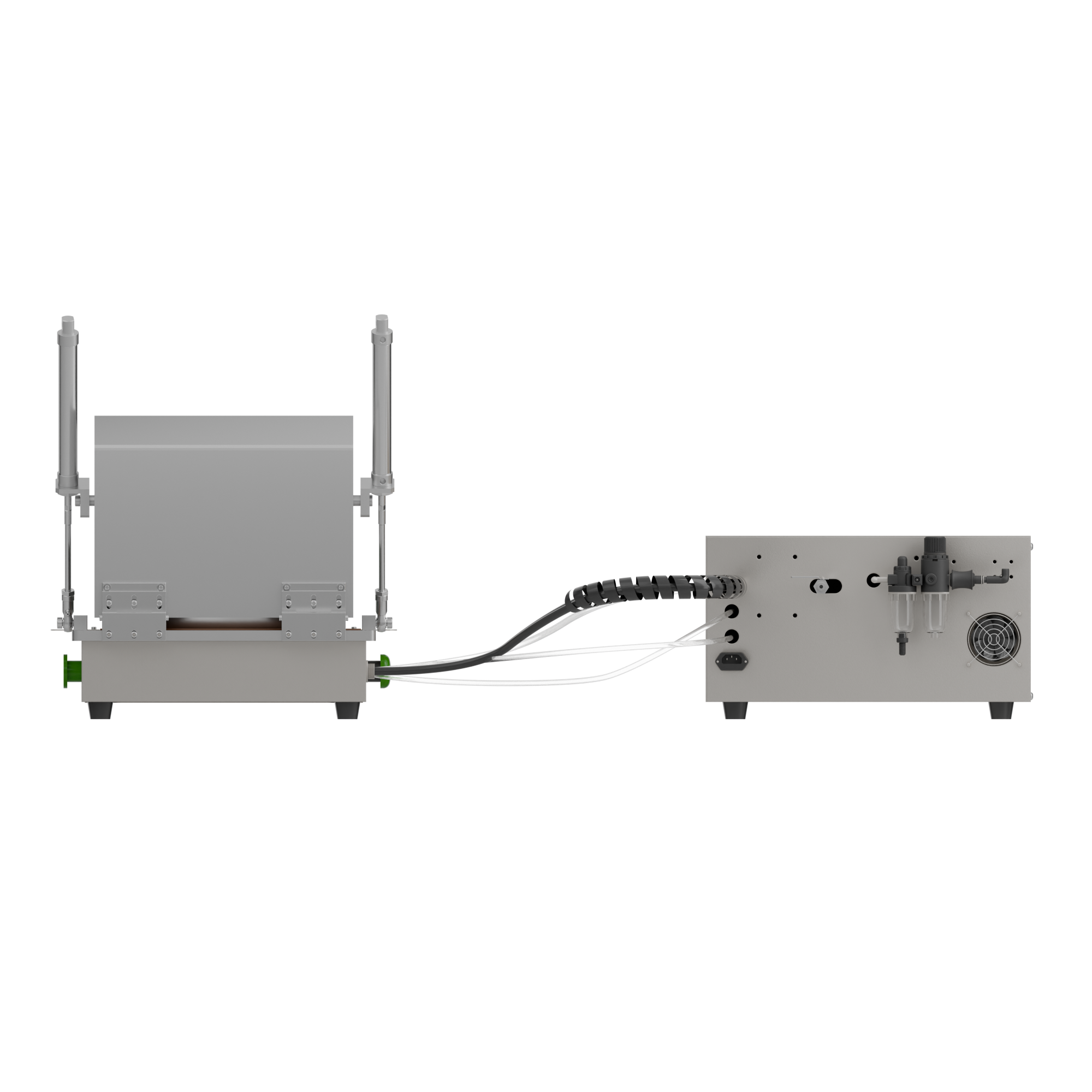

The split design of the host and the control box is adopted, so that the machine can be operated in the glove box or on the assembly line;

Attractive appearance, small size, light weight;

PLC touch screen control, easy and easy to understand.

Technical parameters

PLC touch screen automation control;

The cavity is made of aluminum alloy, with corrosion resistance and firm structure;

Vacuum up-95 kPa adjustable (buyer's own vacuum pump);

Head temperature: room temperature ~250℃, temperature adjustable;

Temperature control accuracy: ± 2℃;

Thermal sealing pressure: 0~5kg/cm2 adjustable;

Hot sealing time: 0~99 seconds adjustable;

Seal edge width: 5±0.4mm (according to customer requirements);

Maximum sealing edge size: 200mm;

Maximum battery range 190mm long, 160mm wide (including air pack position);

Sealing thickness range: 60~300 μm;

Seal thickness accuracy (mm): the package thickness difference of any two points is <15 μm;

Gas consumption: about 0.2L compressed gas/once per seal;

Air pressure working speed: 180 times/h;

Power: 300W heating pipe, the power consumption of about 0.6k W;

Power supply: 220V/50Hz;

Compressed air source: 0.4~0.5Mpa; used in the glove box, the cylinder power source must use the same working gas used in the glove box;

Contour size of the unit

Work Department: 470×485×435mm (L×W×H);

Control box: 420×325×225mm (L×W×H);

Weight: about 50kg.

Categories

Categories