Key features

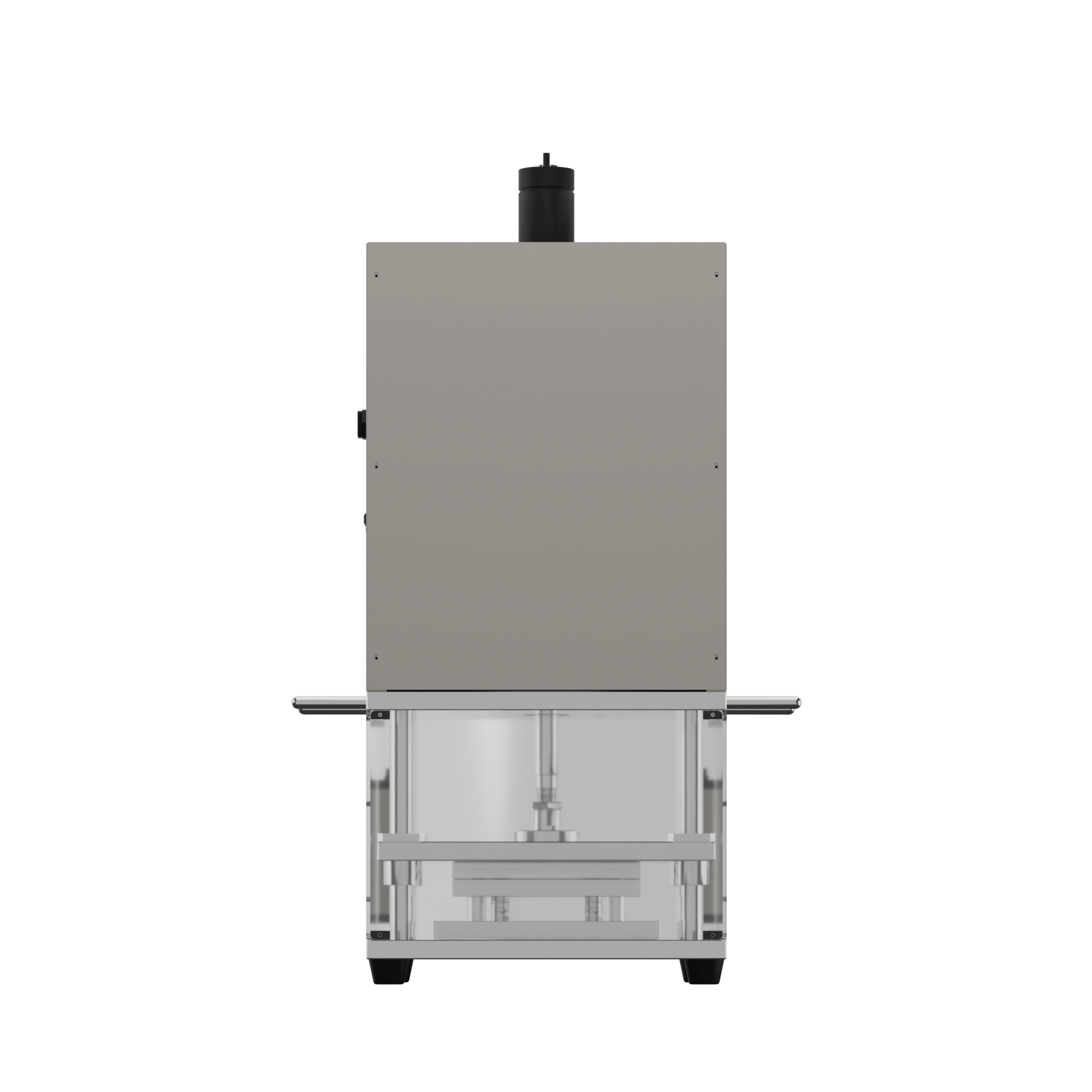

Adopt four guide pillar structure, smooth up and down sliding, high precision.

It is simple and fast to change the mold and adjust the stretching depth.

Compared with similar products, the same quality of aluminum-plastic film is stretched deeper and more stable.

Precise mold design, no crow's feet and collapsed corners in all corners and periphery of the product after molding.

Protected by light curtain and cover, safe to use.

Made of mold materials imported from Japan and high-strength chrome steel and alloy aluminum, the surface has been treated with environmentally friendly electroplating and baking paint.

The appearance is exquisite, and the sheet metal adopts three-dimensional geometric design, which is simple and beautiful;

Easy to operate, safe and reliable, small size.

Technical parameters

Applicable specifications: the maximum length of aluminum plastic film is 180mm, the maximum width is 150mm (it can be customized according to requirements);

Punching depth: punching depth≤6mm; The Pocket is not damaged, and the PP layer has no wrinkles;

Equipment capacity: 200~400EA/H;

Power source: 3T;

Power supply: AC220V/50Hz;

Power: 500W;

Air supply: 0.5MPa~0.7MPa;

Equipment weight: about 150kg;

Equipment size: 460×320×925mm (L×W×H);

Mould part: according to the size of the punching shell;

Mold/core roughness: 0.4;

Flatness of upper and lower molds: 0.02mm;

Core flatness: 0.02mm;

Forming length tolerance: ±0.2mm;

Forming width tolerance: ±0.2mm;

Forming thickness tolerance: ±0.1mm.

Categories

Categories